Flow diagram

The relevance of flow diagrams

Flow diagrams (technical drawings) represent the structure and function of process plants and are therefore essential, superordinate plant documents that form the basis for communication in all phases of the plant life cycle. They are part of the delivery with the purchase of the plant and must therefore be created by the supplier in paper form or digitally after construction and commissioning of the plant.

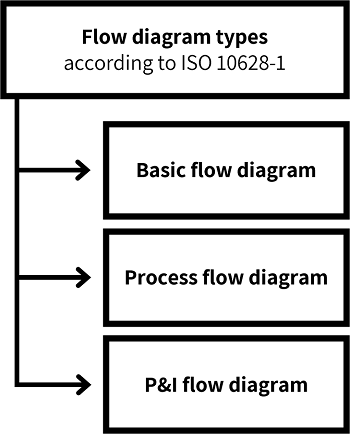

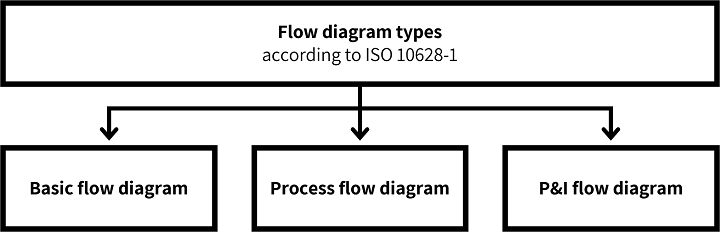

Three types of flow diagrams

The standard DIN EN ISO 10628-1 defines the classification, information content and presentation of flow diagrams and distinguishes between three types of flow diagrams:

- Basic flow diagram for process flow overview – simplified representation of a process or a process plant with the help of rectangles connected by lines.

- Process flow diagram as an explanation of a sub-plant – representation of a process or a process-engineering plant by means of graphic symbols connected by lines.

- Piping and instrumentation flow diagram (P&I flow diagram) with implementation details – more detailed drawing based on the process flow diagram. In addition to the symbols for plant components and pipelines, there are graphic symbols for measurement, regulation and control functions whose representations are specified in ISO 10628-2 (Diagrams for the chemical and petrochemical industry — Part 2: Graphical symbols) and in the DIN 19227 series of standards [withdrawn] (graphical symbols and identifying letters for process measurement and control functions; symbols for basic functions).

The type of diagram thus differs fundamentally in the complexity of the representation, whereby the complexity of the representation is also related to the information content of the document. Thus, the P&I diagram is significantly more extensive in its structure, but thus also provides significantly more information than a basic flowchart.

Type of scheme depends on addressees

The decisive factor for the choice of the type of scheme is the corresponding target group of the document. For example, while potential investors have a more business-oriented plant view and would thus rather use the information content of a simplified representation of the process/plant for investment assessment, a detailed, complete P&I flowchart is of high importance for plant operators.

Relevant standards for the preparation of flow diagrams

For the information content, the standard DIN EN ISO 10628-1 specifies which basic information the respective scheme must contain and which additional information may be present in the document.

The relevant standard DIN EN ISO 10628-1 also refers to the possibility of identifying the objects in the flow diagram by means of the reference identification from the IEC 81346 series of standards. It is thus possible to establish the plant identification in the function-based plant document and consequently also to use the plant identification as a basis for understanding during planning, construction and operation.