Object Model

Object Model

A modern industrial plant is a highly complex network of systems. Numerous different processes must be controlled and coordinated within it. The most important connecting element in this context is the human being. Only people are able to make the right decisions for successful process execution based on knowledge and experience.

For this to be possible, the required knowledge must be available at the right time and in the right place.

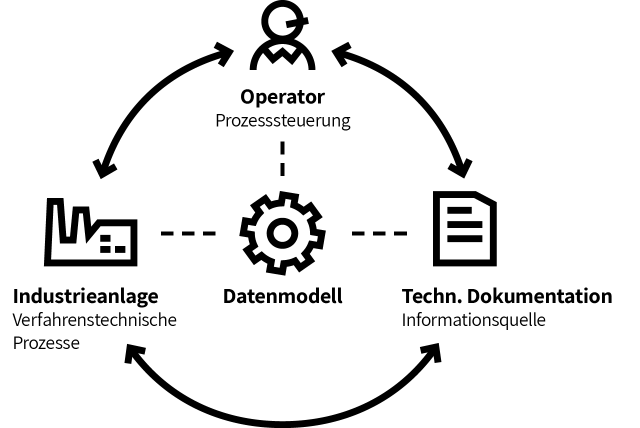

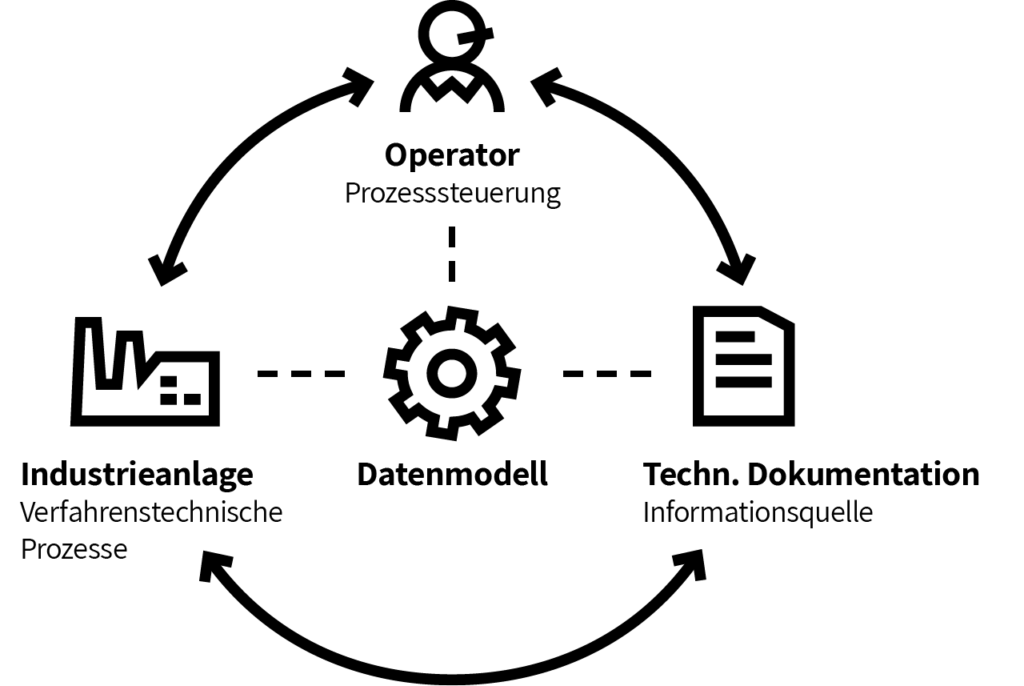

When the operation of an industrial plant is viewed at an abstract level, three distinct components can be defined:

-

The industrial plant as a technical system.

All process engineering, physical, and chemical processes take place within this system. -

The human as the operator.

The operator is the controlling authority that makes the operation of the plant possible in the first place. Through their decisions, they are responsible for the correct control and execution of processes. -

The technical plant documentation.

It contains information about ongoing processes and the condition of the technical system and forms the basis for the operator’s decisions.

To ensure complete and seamless information exchange between these three components, a structured data model is required.

Why a Data Model Is Needed in the First Place

The data model defines the essential relationships between objects that are relevant to the execution of business processes in industrial plants.

It is also intended to support operators in decision-making related to operations management and maintenance organization.

A data model serves as the foundation for analyzing all information required for planning, organizing, and controlling day-to-day operational processes.

To this end, the maintenance and repair processes of an industrial plant are linked with the available information sources.

For example, a maintenance process model enables users to integrate any desired process flow—such as outage planning, safety management, or procurement processes—into the data model.

The data model is designed to improve information availability and management, and to increase efficiency in the use of resources.

Before developing the data model, several questions regarding existing knowledge must be clarified:

- Who needs the knowledge?

- When, or under what conditions, is the knowledge required?

- Where is the knowledge available?

- How is the knowledge maintained and expanded?

- In what form must the knowledge be provided?

Compliance Is a Prerequisite for Any Data Model

A fundamental prerequisite for any data model is compliance with currently applicable standards and guidelines—both with regard to

plant identification

and to the standards governing operations management and maintenance systems.

Without reference to these standards and regulations, a data model would be unusable for the operation of an industrial plant. In addition to the consistent naming of objects and their attributes, it is essential above all to establish a robust structure for uniquely identifying individual components.

Structure of the Model

The fundamental idea behind the development of a data model is to link knowledge management with information from data and document management systems. To achieve this, a selection of different objects must be defined and classified accordingly.

According to European standard EN 81346-1, an object in the general sense is a unit of consideration within a design, planning, implementation, operation, maintenance, and dismantling process.

In addition to a name, each object is assigned specific attributes. In the standard, these are described as “specific viewpoints” or aspects. A unit of consideration may include several such attributes. However, at least one aspect must allow for unambiguous identification.

In a data model, this can be achieved, for example, by applying ISO/TS 16952-10. This standard defines the inventory of power plant assets using a reference designation system.

In addition, individual objects are related to other objects. Each object therefore contains knowledge about various other objects. The relationships between objects within the data model form the bridge between knowledge management and data and document management. In this way, the availability of all information required to execute a business process is ensured.

The connection between two objects, with reference to a unit of consideration, is analyzed in terms of their ability to be related to other objects.

An object therefore consists of:

- its name

- the object description, represented by the various aspects

- and the ability to be related to other objects.

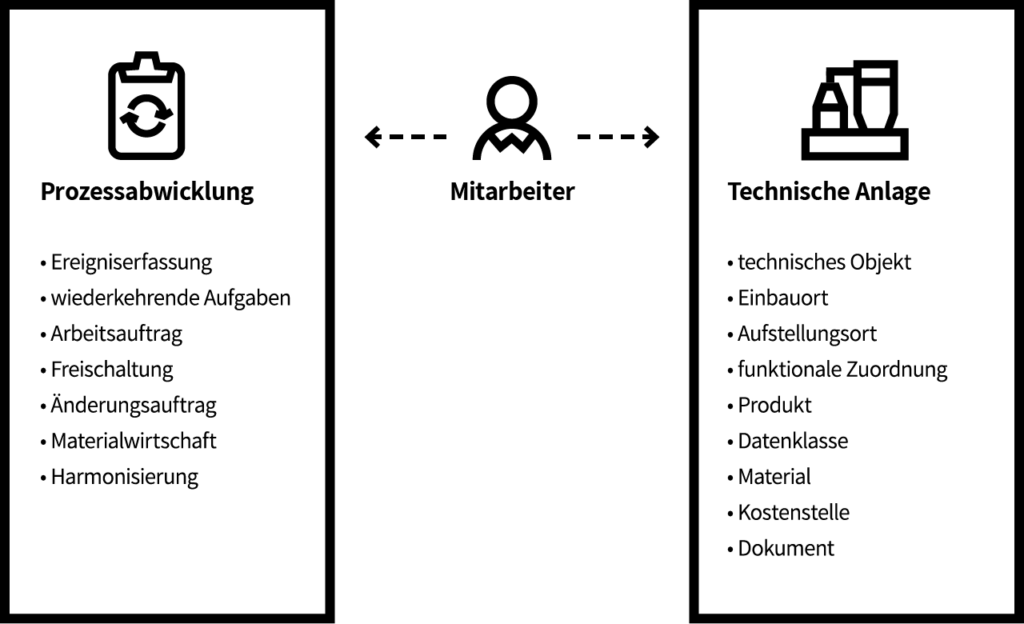

Modeling an Object Model

When modeling an object model, two aspects must be taken into account:

- the complete description of the plant

- the handling of various business transactions within maintenance execution

For this reason, the data model is divided into two areas:

- The objects of the technical plant

- The objects of process execution

In doing so, both the object relationships within the two sub-areas and the overarching relationships are considered.

The separate consideration of the individual sub-areas can provide insights into the information and linkages related to the identification of plant components and systems. In addition, this approach makes it possible to analyze the dependencies and requirements of the individual objects involved in a process.

In the following, the term data model is used exclusively to refer to the overarching model. The two sub-areas, technical plant and process execution, are referred to below as object models.

At the first level of the data model, in addition to the object models

technical plant and process execution,

there is also the object employee. It serves as the link

between the two overarching units of consideration.

As mentioned earlier, the human being is the primary decision-maker and

coordinator. Without an instance of the object employee,

no connection between the technical plant and

process execution is possible.

A business process can only be executed properly if a person draws knowledge

from various information sources and initiates actions based on this knowledge.

Even with a high degree of automation of a technical plant, human intelligence

remains indispensable.